Multi-Axis Precision

5-axis CNC milling capabilities for complex geometries with tolerances to ±0.0001" for critical laboratory automation components.

Advanced Tooling

Custom fixture design and precision tooling optimization for complex laboratory automation part manufacturing.

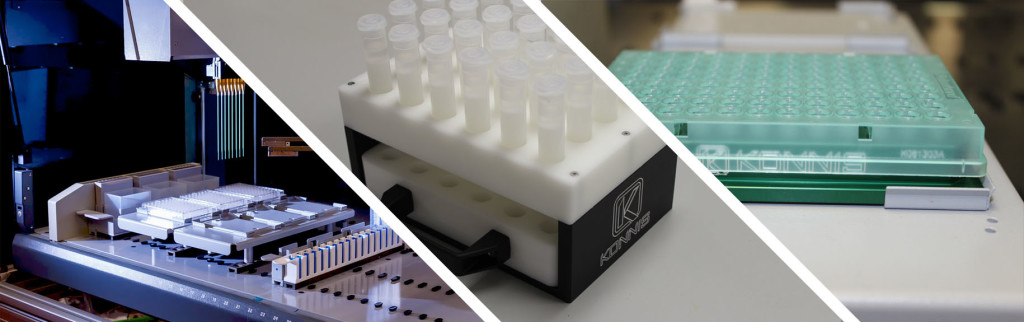

Advanced CNC Milling Services for Laboratory Automation

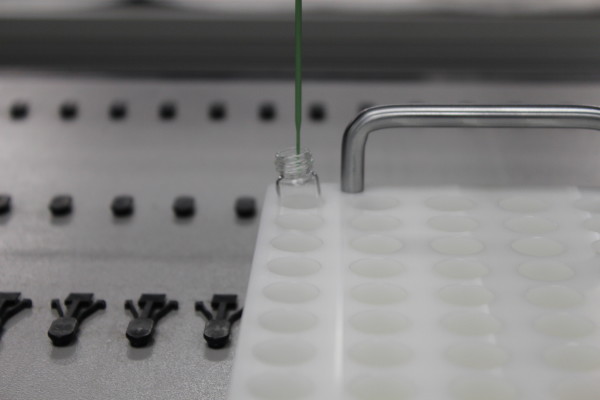

Konnis delivers precision CNC milling services specifically designed for the demanding requirements of laboratory automation manufacturers. Our advanced multi-axis machining capabilities, combined with specialized tooling and fixture design expertise, enable us to produce complex automation components with exceptional accuracy and surface finish quality. From prototype to production, we ensure every part meets the exacting standards required for reliable liquid handling performance.

Advanced CNC Milling Capabilities

Multi-Axis Machining Centers

Our state-of-the-art CNC milling equipment includes 3, 4, and 5-axis machining centers capable of producing complex geometries in a single setup. This multi-axis capability eliminates the need for multiple fixturing operations, ensuring superior dimensional accuracy and reducing production time for intricate laboratory automation components.

5-Axis Simultaneous Machining

Advanced 5-axis simultaneous machining allows us to create complex undercuts, angled features, and curved surfaces that would be impossible with conventional 3-axis milling. This capability is essential for modern laboratory automation components requiring sophisticated geometries for optimal performance.

High-Speed Machining

Our high-speed machining capabilities enable rapid material removal while maintaining exceptional surface finish quality. This is particularly important for aluminum carriers and adapters where both dimensional accuracy and aesthetic appearance are critical.

Precision Tooling & Fixture Design

Custom fixture design is critical for achieving consistent quality in precision CNC milling operations. Our engineers design and manufacture specialized work-holding fixtures that ensure repeatable part positioning and minimize workpiece distortion during machining.

Modular Fixturing Systems

We utilize modular fixturing systems that can be quickly reconfigured for different part geometries, enabling cost-effective production of both prototype and production quantities. This flexibility is essential for laboratory automation manufacturers requiring rapid design iterations.

Vacuum Clamping Technology

Advanced vacuum clamping systems allow us to securely hold thin-walled components and delicate parts without inducing stress or distortion. This technology is particularly valuable for machining precision microplate carriers and thin adapter plates.

Surface Finish Specifications

Ra Surface Finish Control

We achieve surface roughness values as low as Ra 0.1 μm (4 μin) on critical surfaces through optimized tooling selection, cutting parameters, and finishing operations. This level of surface quality is essential for laboratory automation components requiring smooth liquid flow or precise optical properties.

Anodized Surface Compatibility

Our machining processes are optimized for aluminum alloys that will receive anodized finishes. We control surface texture and eliminate tool marks that could create visual defects in the final anodized coating, ensuring professional appearance for laboratory automation equipment.

Functional Surface Treatments

Beyond aesthetic considerations, we can machine specific surface textures for functional purposes such as improved grip surfaces on manual handling areas or controlled surface roughness for adhesive bonding applications.

Dimensional Accuracy Standards

Our CNC milling operations maintain dimensional tolerances to ±0.0001" (±0.0025mm) on critical features when required. This level of precision is achieved through:

- Temperature-controlled machining environment

- High-precision measuring equipment and in-process inspection

- Rigorous tool wear monitoring and compensation

- Statistical process control for consistent quality

Laboratory Automation Component Specialization

Precision Microplate Carriers

Our CNC milling expertise enables production of highly accurate microplate carriers that ensure proper labware positioning for reliable liquid handling operations. Key features include:

- SBS-Standard Compliance - Precise adherence to Society for Biomolecular Screening dimensional standards

- Multi-Position Configurations - Single or multiple microplate positions with exact spacing

- Raised Platform Design - Optimized clearance for robotic access and optical scanning

- Corner Chamfers & Radii - Smooth edges for safe handling and equipment protection

Custom Tube Rack Adapters

Specialized CNC milling techniques for producing tube rack adapters with precise hole patterns and depths:

- 1.5ml Microcentrifuge Tubes - Precise bore diameter and depth for secure tube positioning

- 5ml and 15ml Conical Tubes - Tapered bore geometry matching tube profile

- PCR Strip Tube Holders - Multi-cavity designs with exact pitch dimensions

- Custom Tube Formats - Adaptation for specialty tubes and vials

Complex Gripper Interface Components

Advanced CNC milling for robotic gripper interfaces requiring complex three-dimensional geometries and precise mating surfaces. These components often feature:

- Angled gripper pad mounting surfaces

- Integrated fastener access holes

- Stress-relief features to prevent cracking

- Precision alignment pins and locating features

Material Expertise for Laboratory Environments

Aluminum Alloy Selection

We specialize in machining aluminum alloys optimized for laboratory automation applications:

- 6061-T6 Aluminum - Excellent machinability with good corrosion resistance

- 7075-T6 Aluminum - High strength for structural components

- MIC-6 Cast Aluminum Plate - Superior flatness and dimensional stability

- Anodizing-Grade Alloys - Optimized for high-quality surface finishes

Stainless Steel Machining

When chemical resistance is paramount, we machine various stainless steel grades using specialized tooling and cutting parameters optimized for these challenging materials:

- 316L Stainless Steel - Superior corrosion resistance for harsh chemical environments

- 17-4 PH Stainless Steel - High strength and hardness after heat treatment

- Custom Passivation - Enhanced corrosion resistance through controlled surface treatment

Engineering Plastic Machining

Advanced machining techniques for high-performance plastics used in specialized laboratory automation applications:

- PEEK (Polyetheretherketone) - Chemical resistance and temperature stability

- POM (Polyoxymethylene) - Dimensional stability and low friction

- PTFE (Teflon) - Ultimate chemical inertness with specialized workholding

Quality Control & Inspection

Advanced Metrology Equipment

Our quality control department utilizes state-of-the-art measuring equipment to verify dimensional accuracy:

- Coordinate Measuring Machine (CMM) - Three-dimensional inspection of complex geometries

- Optical Comparators - High-precision measurement of profiles and features

- Digital Micrometers & Calipers - Certified to NIST standards for dimensional verification

- Surface Roughness Testers - Quantitative measurement of surface finish quality

Statistical Process Control

We implement rigorous statistical process control (SPC) methods to ensure consistent quality across production runs. This includes real-time monitoring of critical dimensions and automatic adjustment of machining parameters when variations are detected.

Material Certification

Full material traceability and certification is provided for all manufactured components, including mill test certificates and compliance documentation for regulated laboratory environments.

Industry Applications & Use Cases

Pharmaceutical & Biotechnology

Our precision CNC milling services support pharmaceutical and biotechnology applications requiring:

- High-throughput screening automation components

- Assay development and validation hardware

- Drug discovery liquid handling optimization

- Cleanroom-compatible manufacturing processes

Clinical Diagnostics

Clinical laboratory automation benefits from our expertise in:

- Sample preparation automation hardware

- Diagnostic instrument integration components

- Quality control standard positioning systems

- Barcode scanning and tracking hardware

Academic & Research Institutions

Research applications requiring custom automation solutions:

- Novel assay development platforms

- Experimental automation prototypes

- Custom liquid handling research tools

- Educational laboratory automation systems

Contract Research Organizations

CRO requirements for flexible and adaptable automation hardware:

- Multi-client platform compatibility

- Rapid reconfiguration capabilities

- Scalable production solutions

- Cost-effective custom manufacturing

Design for Manufacturing (DFM) Consultation

Optimization for CNC Milling

Our engineers provide design for manufacturing consultation to optimize part designs for CNC milling production:

- Feature Accessibility - Ensuring all features can be machined with standard tooling

- Material Utilization - Optimizing part orientation and nesting for minimal waste

- Tolerance Analysis - Identifying which dimensions require tight control vs. standard tolerances

- Surface Finish Requirements - Balancing quality requirements with production efficiency

Cost Optimization Strategies

We work with clients to identify cost reduction opportunities without compromising functionality:

- Alternative material selection for equivalent performance

- Feature simplification to reduce machining time

- Batch production strategies for improved economies of scale

- Standard fastener and hardware integration

Rapid Prototyping to Production

Prototype Development Services

Fast-turnaround prototype development allows for rapid design validation and iteration:

- Express Machining - Rush prototypes in 24-48 hours when required

- Material Flexibility - Prototype in final material or cost-effective alternatives

- Design Iteration Support - Multiple revision cycles with quick turnaround

- Functional Testing - Parts ready for immediate integration and testing

Production Scaling Services

Seamless transition from prototype to production quantities:

- Production fixture and tooling development

- Process optimization for volume manufacturing

- Quality system implementation for production control

- Supply chain management for material procurement

Why Choose Konnis for CNC Milling Services?

- Laboratory Automation Expertise - Deep understanding of liquid handling precision requirements

- Advanced Multi-Axis Capabilities - Complex geometries machined in single setups

- Precision Tooling & Fixturing - Custom work-holding solutions for optimal accuracy

- Superior Surface Finishes - Ra 0.1 μm achievable on critical surfaces

- Tight Tolerance Control - ±0.0001" capability when required

- Material Expertise - Optimized processes for aluminum, stainless steel, and engineering plastics

- Design for Manufacturing - DFM consultation for cost-effective production

- Rapid Prototyping - Fast turnaround for design validation

- Quality Assurance - Advanced metrology and statistical process control

- In-House Control - Complete manufacturing process under one roof

Getting Started with Your CNC Milling Project

Ready to discuss your precision CNC milling requirements? Our team of manufacturing engineers and CNC specialists is ready to help you develop the optimal solution for your laboratory automation component needs. Whether you need a single prototype or production quantities, we have the capabilities and expertise to deliver exceptional results.

Contact us today to discuss your project requirements and learn how our advanced CNC milling capabilities can enhance your laboratory automation performance while reducing costs and improving time-to-market.

Get Manufacturing QuoteStart Your Automation Journey Today

Ready to reduce costs and improve performance? Partner with Konnis to bring custom automation and precision-engineered solutions to your lab—without the OEM price tag.

Gret A Free Quote Today