Complex Geometries

Create intricate internal channels, precise slots, and complex cutouts impossible with conventional machining methods.

Stress-Free Machining

No mechanical cutting forces means delicate parts maintain dimensional accuracy without warping or distortion.

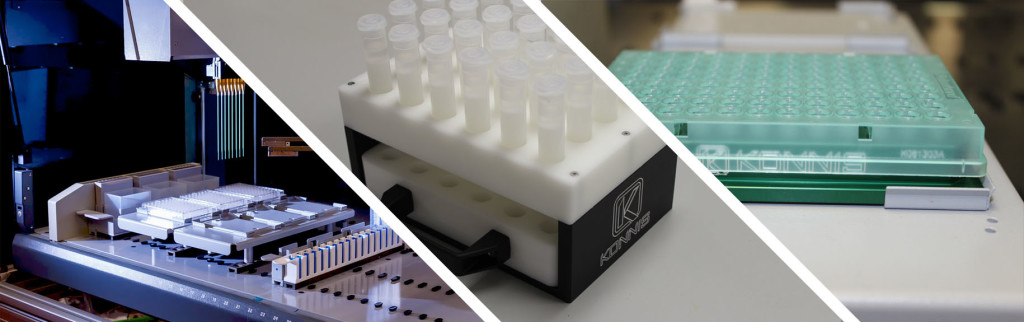

Specialized EDM Manufacturing for Liquid Handling Components

Konnis utilizes electrical discharge machining (EDM) technology to create complex liquid handling automation components that would be impossible or impractical with conventional machining. Our wire EDM and sinker EDM capabilities enable us to produce intricate internal features, precise cutouts, and delicate geometries essential for modern liquid handling applications.

EDM Technology for Liquid Handling Applications

Why EDM for Laboratory Automation?

EDM is a thermal machining process that removes material through controlled electrical discharges, making it ideal for liquid handling components requiring:

- Complex Internal Channels - Fluid pathways with precise dimensions and smooth walls

- Sharp Internal Corners - Clean intersections impossible with round cutting tools

- Delicate Features - Thin walls and fine details without mechanical stress

- Hard Material Processing - Machine hardened components without softening

- Burr-Free Edges - Clean cuts essential for proper sealing and function

No-Contact Manufacturing Benefits

The absence of mechanical cutting forces provides critical advantages for liquid handling components:

- Eliminates part distortion during machining

- Prevents stress-induced cracking in delicate features

- Enables machining of thin-walled components

- Maintains tight tolerances throughout the process

Wire EDM Services

Precision Wire Cutting Capabilities

Our wire EDM systems use ultra-thin wire electrodes to create precise cuts and intricate profiles in conductive materials with exceptional accuracy.

Wire EDM Specifications

- Cutting Accuracy - ±0.0002" (±0.005mm) positional tolerance

- Surface Finish - Ra 0.2-0.8 μm depending on application requirements

- Material Thickness - Up to 8" thick materials for large components

- Wire Diameter - 0.004" to 0.010" for varying detail requirements

Liquid Handling Component Applications

Carrier and Adapter Cutouts

Wire EDM excels at creating complex access patterns for liquid handling automation:

- Robotic Gripper Access Slots - Precise openings for reliable plate handling

- Pipette Tip Access Channels - Clean pathways for tip loading and ejection

- Sensor Integration Cutouts - Complex shapes for barcode scanners and level sensors

- Fluid Overflow Channels - Controlled drainage paths to prevent cross-contamination

Custom Labware Interface Features

- Precision plate positioning slots

- Tube rack interface patterns

- Reagent bottle mounting cutouts

- Temperature probe access holes

Sinker EDM Services

Complex Internal Cavity Creation

Sinker EDM uses custom electrodes to create three-dimensional cavities and internal features impossible with other machining methods.

Liquid Handling Applications

Fluid Manifold Manufacturing

Create complex internal flow passages for liquid distribution systems:

- Multi-Channel Manifolds - Precise internal routing for reagent distribution

- Mixing Chambers - Optimized geometry for consistent fluid mixing

- Valve Integration Pockets - Precise cavities for valve mounting

- Pressure Relief Features - Internal geometry for safe pressure management

Custom Gripper Components

Specialized gripper parts requiring precise internal features:

- Vacuum channel systems for secure plate gripping

- Pneumatic actuation chambers

- Custom jaw profiles for specific labware

- Integrated sensor mounting pockets

Material Capabilities

Aluminum Alloys

EDM processing of aluminum components commonly used in liquid handling systems:

- 6061-T6 Aluminum - Standard carrier and adapter material

- 7075-T6 Aluminum - High-strength applications requiring durability

- Anodized Surfaces - Can machine pre-anodized components when necessary

Stainless Steel Processing

For chemical resistance and cleanroom compatibility:

- 316L Stainless Steel - Superior corrosion resistance for harsh environments

- 17-4 PH Stainless - High strength applications in hardened condition

- Custom Passivation - Enhanced corrosion resistance post-EDM

Specialized Materials

- Tool steels for wear-resistant components

- Titanium for biocompatible applications

- Inconel for extreme temperature resistance

Quality Control and Precision

Dimensional Accuracy

Our EDM processes maintain exceptional precision critical for liquid handling performance:

- Wire EDM - ±0.0002" tolerance on critical dimensions

- Sinker EDM - ±0.0005" cavity dimensional control

- Surface Location - Precise positioning for proper assembly

- Repeatability - Consistent results across production quantities

Surface Quality Control

Multi-pass EDM strategies optimize surface finish for liquid handling applications:

- Roughing passes for efficient material removal

- Finishing passes for dimensional accuracy

- Surface optimization for fluid flow applications

- Deburring and edge finishing as required

Design for EDM Manufacturing

Optimization Guidelines

Our engineering team helps optimize designs for EDM manufacturing:

- Feature Accessibility - Ensure electrode or wire access to all features

- Material Selection - Choose electrically conductive materials

- Corner Radii - Optimize for wire diameter or electrode requirements

- Surface Finish Requirements - Balance quality needs with production efficiency

Hybrid Manufacturing Strategies

Combining EDM with conventional machining for optimal results:

- CNC rough machining followed by EDM finishing

- EDM internal features with CNC external surfaces

- Post-EDM conventional finishing operations

Applications in Liquid Handling Automation

Tecan Instrument Components

Specialized EDM manufacturing for Tecan liquid handling systems:

- Custom carrier modifications with precise cutouts

- Adapter plates with complex access patterns

- Gripper interface components

- Sensor integration brackets

Custom Automation Solutions

EDM manufacturing for unique liquid handling requirements:

- Prototype component development

- One-off research apparatus parts

- Custom assay-specific hardware

- Integration components for third-party devices

Precision Tooling and Fixtures

- Assembly fixtures with precise locating features

- Go/no-go gauges for quality control

- Calibration standards and references

- Custom jigs for repetitive operations

Production Capabilities

Prototype to Production

Flexible manufacturing approach supporting development through production:

- Rapid Prototyping - Quick turnaround for design validation

- Small Batch Production - Cost-effective quantities for specialized applications

- Production Scaling - Efficient processes for larger volumes

- Design Iteration Support - Multiple revisions with fast turnaround

Integration with Other Services

EDM manufacturing integrated with our complete liquid handling services:

- CNC machining for complete assemblies

- Laser marking for part identification

- Assembly and testing services

- Integration with refurbished instrument upgrades

Why Choose Konnis for EDM Manufacturing?

- Liquid Handling Expertise - Deep understanding of automation component requirements

- Precision EDM Technology - Wire EDM and sinker EDM capabilities

- Complex Geometry Capability - Features impossible with conventional machining

- Material Expertise - Aluminum, stainless steel, and specialized alloys

- Quality Control - ±0.0002" tolerances and superior surface finishes

- Design Support - Engineering consultation for EDM optimization

- Integrated Services - Complete manufacturing and automation solutions

- Tecan Specialization - Extensive experience with Tecan system components

Getting Started

Ready to explore how EDM technology can solve your complex liquid handling component manufacturing challenges? Our team combines deep automation expertise with advanced EDM capabilities to create solutions that conventional machining cannot achieve.

Contact us today to discuss your EDM manufacturing requirements and discover how our specialized capabilities can bring your most challenging liquid handling designs to life.

Get Manufacturing QuoteStart Your Automation Journey Today

Ready to reduce costs and improve performance? Partner with Konnis to bring custom automation and precision-engineered solutions to your lab—without the OEM price tag.

Gret A Free Quote Today